Cable lugs

Made by Schulte

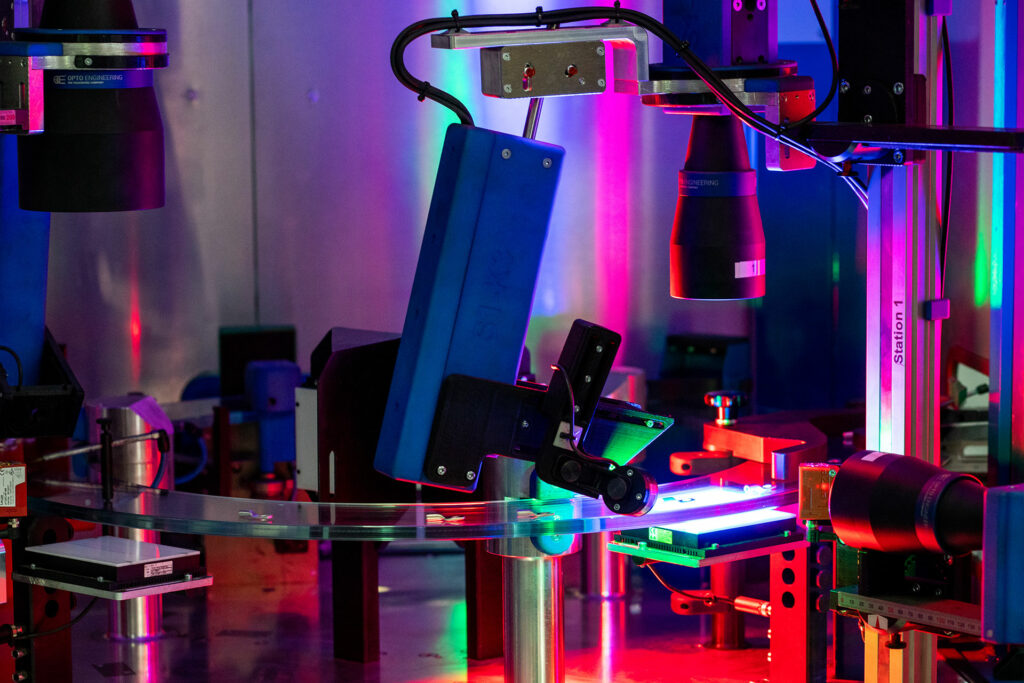

Secure connections

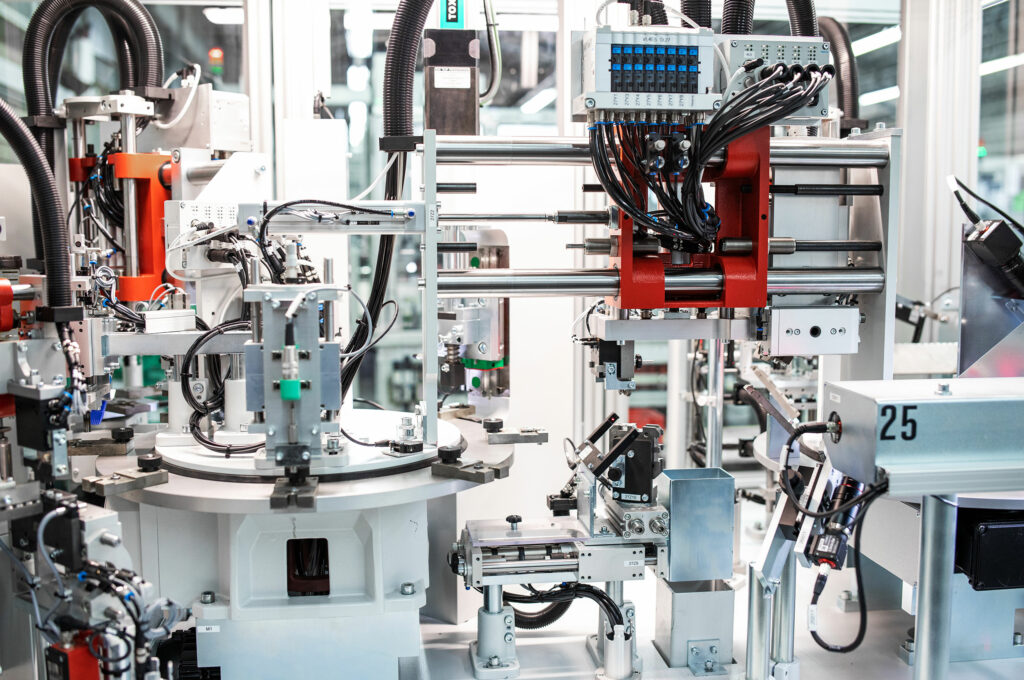

We develop and manufacture tubular cable lugs, stamped cable lugs and forged cable lugs for use in motor vehicles and other industrial sectors as individual parts or as strip goods for high-volume processing. In the process, the cable lugs are manufactured in many different processes in order to always be able to adequately respond to the respective customer requirements.

Pipe-

Cable lugs

Tubular cable lugs are used wherever high mechanical strength and individual design options in specific installation spaces are required. Highly conductive copper as the base material ensures excellent electrical conductivity. Galvanically applied tin layers adapted to the environmental requirements ensure corrosion resistance, a flawless visual impression and long-term electrical stability.

Tubular cable lugs with integrated nuts

Maximum comfort and safety during processing with optimum economy are offered by the tubular cable lugs with integrated nuts or bolts, which allow direct processing without the addition of further screw elements during assembly in our customers' automotive plants.

Special technical solutions are also possible - for example, stainless steel screw elements, specially coated components or even magnetized products are used.

We also have the right product for the increasing demands on the tightness of electrical connections in the engine compartment. Cable lugs, which are made watertight by a special surface post-treatment process, ideally permit the production of cables used in splash water areas and, in conjunction with suitable heat-shrink tubing, prevent water from penetrating the wiring harness.

Punch

Cable lugs

Stamped cable lugs are manufactured as individual parts or for high-volume processing as strip goods. The basic material range extends from the use of economical brass materials to highly conductive copper-iron alloys coated with electroplated tin layers, which excellently permit both long-term stable crimping technology and welding processing. The flexible crimp claw design meets the demanding standards of automotive manufacturers and offers the user the possibility of using different cross-sections in one contact part.

Forge-

Cable lugs

Forged cable lugs are used wherever high mechanical stability is required under difficult installation space conditions. High temperatures, vibration loads, confined installation space and angled geometries are the requirements that lead to the use of forged cable lugs. Additional screw bolts, the integration of external starting points as well as threads for further contacting are just some of the extensive additional applications that forging technology allows here.